A Guide to Commercial Plywood Adhesives: Performance, Durability, and Safety

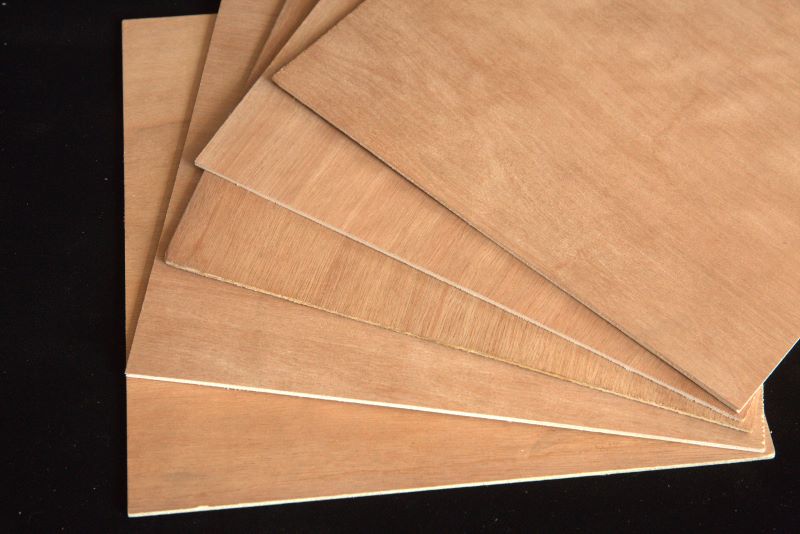

While plywood buyers often focus on thickness, core material, or surface grade, the adhesive is the silent engine behind a board's performance. The glue choice determines everything from structural integrity and moisture resistance to the air quality of the final environment.

Understanding the adhesives used in commercial plywood is essential for selecting the right materials for furniture, cabinetry, and interior fit-outs.

Why Glue is the Foundation of Plywood Quality

Glue is the "bonding agent" that holds multiple veneer layers together. Even the highest-quality wood veneers will fail if the adhesive is subpar. In the commercial plywood industry, glue selection directly impacts:

• Structural Integrity: Prevents delamination and warping.

• Moisture Resistance: Determines how the board reacts to humidity.

• Safety Standards: Controls formaldehyde emission levels.

• Longevity: Ensures the furniture or cabinet lasts for years without failing.

3 Primary Glue Types in Commercial Plywood

Manufacturers generally utilize three main adhesive systems, each tailored to specific performance needs and budget levels.

1. Urea Formaldehyde (UF) Glue

The Standard for Interior Applications

UF glue is the most common adhesive in the commercial plywood market. It is favored for its cost-efficiency and excellent bonding strength in dry environments.

• Best For: Wardrobes, bedroom furniture, and interior wall panels.

• Pros: Fast curing, high bond strength in dry conditions, and low cost.

• Cons: Limited resistance to water and high humidity.

2. Melamine Urea Formaldehyde (MUF) Glue

The Moisture-Resistant Upgrade

By adding melamine resin to the UF formula, manufacturers create a more durable bond that can withstand occasional moisture.

• Best For: Kitchen cabinets, bathroom vanities, and projects in coastal regions.

• Pros: Enhanced moisture resistance and stronger overall durability than standard UF.

• Cons: Slightly higher production cost.

3. Phenolic Glue (PF)

The Premium Choice for Maximum Durability

3. Phenolic Glue (PF)